Powder coatings

Anodised effects with powder coatings

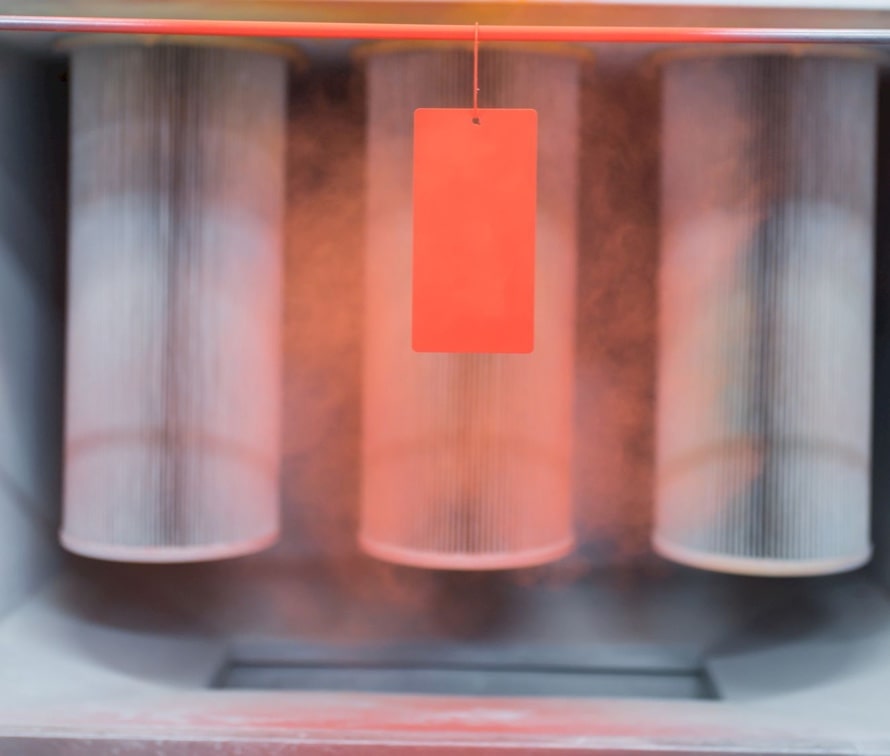

With the new powder coating series PP7001K, FreiLacke has developed a new coating system with anodised colours. The established colours from the anodising of aluminium served as the basis for the colour shades. As the coatings have a polyester base, components with this powder coating are particularly suitable for outdoor applications.

To protect aluminium against corrosion, a protective oxide layer is produced by anodic oxidation. This anodised layer is very hard and scratch-resistant; however, it is also very brittle, which is why workpieces must be fully shaped before they are anodised.

Furthermore, the process costs of the anodising process are relatively high. This is why there have been frequent attempts to replace the anodised layer with a powder coating. Visually, the oxide layer has a very matt, velvety surface. The colour of the oxide layer can be changed using colourising metal salts in the electrolyte or by using organic or inorganic dyes.

What exactly are Eloxal anodised coatings?

The term Eloxal comprises the first two letters of three words and stands for the electrolytic oxidation of aluminium. To protect light alloys against corrosion, a protective layer is created by anodic oxidation. This ‘Eloxal’ anodised layer is extremely hard and scratch-resistant. However, it is also very brittle. Because of this, workpieces need to be fully shaped before they get anodised. In addition, the Eloxal anodising process is relatively expensive. FreiLacke has therefore endeavoured successfully to replace the anodised layer with a powder coating that retains all the benefits of anodised coatings.

Using different processes to simulate Eloxal coatings

Visually, the Eloxal layer, simulating a powder coating, has a very matt, and velvety surface. It can be coloured in various different ways, specifically:

- with the help of colouring metal salts and alternating voltage in the electrolyte, with the desired intensity of colour dependent on the duration of the electrolysis process;

- with organic fillers, involving the immersion of components in a coating solution followed by a rinsing process – where most of the molecules of colouring agent (dyes) are deposited in the upper areas of the pores in the powder oxide layer;

- or with inorganic colouring agents or dyes which involve the affected workpiece being neutralised, rinsed and then coloured in baths containing metallic salt solutions.

Would you also like to benefit from the advantages of Eloxal coating – such as high scratch and corrosion resistance – without losing access to a wide selection of visually convincing coatings? If so, then you should opt for a powder coating from FreiLacke that looks similar to the familiar Eloxal coatings. Please do not hesitate to contact us.