Values embodied for more than three decades

Sustainability, states Tobias Kehl, “has been a fixed component of our company culture for more than 30 years”. He ought to know. After all, firstly, Tobias Kehl is Head of the Quality, Environment & Safety department at coatings specialist Emil Frei GmbH & Co. KG in Bräunlingen-Döggingen. And, secondly, he has a great and in-depth knowledge of the company: The 42-year old began his education as a chemicals specialist at FreiLacke 25 years ago.

In his view, sustainability, a multi-faceted topic, has always been a guiding principle for corporate development at FreiLacke. And there is yet more: this has been true at FreiLacke ever since the mid-Nineties, before the United Nations Sustainable Development Goals (SDGs) came into existence.

Resource-conserving targets defined back in 1996

For Tobias Kehl, EMAS-compliant validation of environmental performance, “which FreiLacke has consistently achieved every year, ever since 1996”, is a key factor in achieving even higher levels of sustainability. EMAS stands for the Eco Management and Audit Scheme. It is also referred to as the Eco-Audit and was devised by the European Union. EMAS enshrines environmental management as well as a form of environmental audit – in other words, it is a tool to assist with improvement. A tool which has helped this family-owned company to improve its environmental footprint in many areas. On a regular basis during the EMAS validation process, specific targets were defined for reducing energy and fresh water consumption.

Production improved, energy consumption reduced

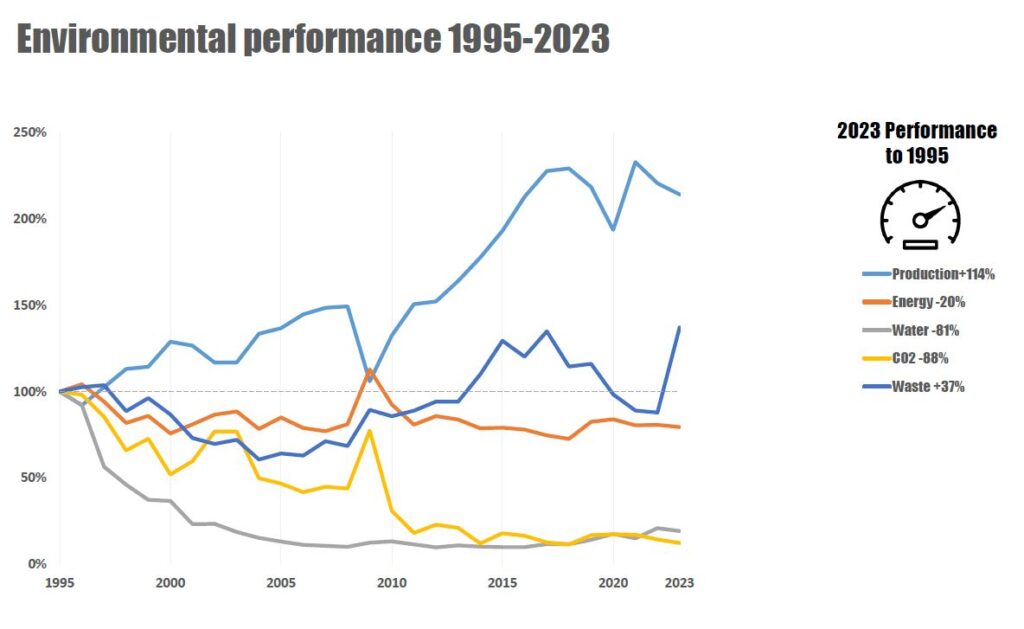

In 1995, the company’s energy consumption was still 627 kilowatt hours per tonne (kWh/t). In 2023, it was only 498 kWh/t. From FreiLacke’s point of view, this reduction of almost 20 per cent is all the more exciting because production volume has more than doubled over the same period and the products being manufactured are more energy-intensive to produce. But that is not all: Despite this increase in output, water consumption today is around 80 per cent lower than it was in 1995. The CO² emissions for the manufacture of the products have also fallen – “they have been reduced by a good 88 per cent”, reports Tobias Kehl. FreiLacke is therefore well on the way to achieving its major goal: “We want our production to be climate-neutral from 2025”. However, the 42-year-old emphasises that ecological improvements are not an end in themselves: “We feel it is very important indeed to combine ecological improvements with economic success”.

Challenges are not diminishing

In spite of everything, it will remain a challenge for FreiLacke “to comply with and to implement the increasingly stringent regulatory requirements”. Tobias Kehl is quite certain of that. One factor in this matrix of issues is substitution – the replacement with low-risk substances of chemicals that are categorised as hazardous. The challenge here is to maintain the high quality standard of products despite changes to their material composition. “This hazard categorisation by the European Chemicals Agency can change every year”, states the sustainability manager, describing the difficult task involved: “We regularly update and improve our products and processes to reduce the risk to our employees, customers and the environment. Our aim is to develop better products through innovation. This can only be achieved through close cooperation with our suppliers and with qualified specialists who must have very good knowledge of the raw materials used, the statutory stipulations and customer requirements”. Tobias Kehl estimates that this is another reason why research and development expenditure amounts to three to four per cent of annual turnover.

Dialogue really helps

The manager goes on to explain that, even though FreiLacke is well resourced with in-house experts, dialogue with other specialists is of great benefit. “Associations such as the Association of the German Coating and Printing Ink Industry or networks such as the wvib sustainability cluster have an important contribution to make”.

A major role – also in terms of sustainability – is played by social responsibility towards employees, residents and the local community. The CEO is aware of this. “At an early point, we recognised that fair pay, training and development opportunities and flexible working time models are success factors”, says the family man. Appropriately, the company’s shareholders have created the Emil Frei Foundation, an organisation that focuses on social projects.

Focus on the future

To ensure that FreiLacke is well positioned for the future, the company is currently developing a strategy for how it will be organised by 2032. Sustainability will be an important part of this and will be taken into account in all aspects, explains Tobias Kehl: “FreiLacke is organising this process along very open lines, enabling employees from all areas can participate alongside managers – and I am very much looking forward to helping them navigate this course over the next eight years”.

What does sustainability mean to me?

“Right across the board, I try to avoid waste and to consume less, either by using material items or by keeping them for as long as possible”.

Tobias Kehl

To ensure that FreiLacke is well positioned for the future, the company is currently developing a strategy for how it will be organised by 2032. Sustainability will be an important part of this and will be taken into account in all aspects, explains Tobias Kehl: “FreiLacke is organising this process along very open lines, enabling employees from all areas can participate alongside managers – and I am very much looking forward to helping them navigate this course over the next eight years”.

Info box

Name: Tobias Kehl

Position: Leitung Qualität, Umwelt, Sicherheit

Company: Emil Frei GmbH & Co. KG, better known as FreiLacke

EMail: t.kehl@freilacke.de